Sugar Grinding

Sugar or sucrose occurs naturally in all fruits and vegetables and is industrially obtained from sugar cane or sugar beet. Due to its sweetening power it is used for taste enhancing of a large number of food products. Additionally, it is often added to products for functional aspects, such as lowering the water activity or improving the texture.

Applications

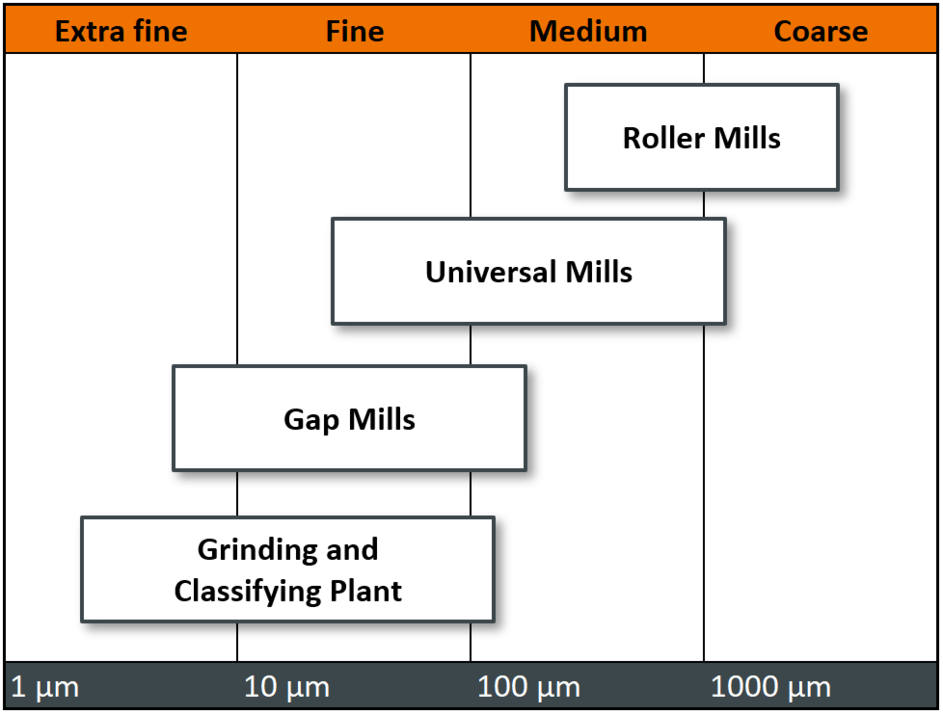

Depending on the food industry and intended product, a wide range of particle size distributions of sugar are required demanding a large flexibility of the mills. While the crystalline sugar types are produced with sieve classifiers, the fine products need to be ground in a mill. Bauermeister offers three different mill types that can satisfy all requirements. Ranging from very fine to coarsely milled sugar, wide or narrow particle size distributions or a low content of fines we can offer a standard or specialized solution that meets your specifications.

Possible Applications Of Fine Ground Sugar

Chocolate / Fillings: | <20...30 µm | Gap Mill (+ Air Classifier) |

Cookies / Confectionary: | <100...150 µm | Universal Mill / UCOM |

Instant Drinks: | 100…600 µm | Roller Mill |

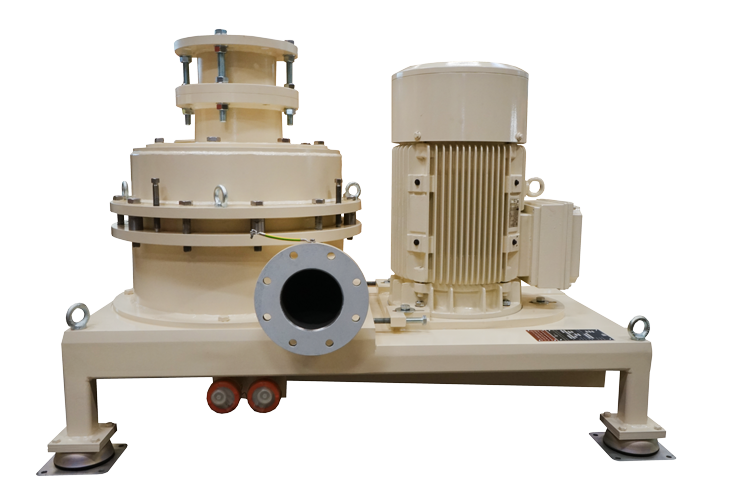

Gap Mills

If a fineness of up to 99 % < 40 µm is required, the Bauermeister Gap Mill is the perfect choice. For extrafine products the Gap Mill can be combined with a classifier to reach up to 99 % < 25 µm. Depending on the mill size and required fineness an output of up to 4,500 kg/h can be reached.

Sugar grinding capacities of different GM sizes

Particle size | GM 40.1 (N) Ex | GM 80.1 (N) Ex | GM 120.1 (N) Ex |

|---|---|---|---|

>95% < 30 µm | 500 kg/h | 1000 kg/h | – |

>95% < 50 µm | 1000 kg/h | 2000 kg/h | – |

>95% < 90 µm | 1500 kg/h | 3000 kg/h | 4500 kg/h |

Universal Mills

Sugar grinding capacities of different UM/UCOM sizes for sugar grinding

Particle size | UMT 0.3* | UMT 1.3* | UMT 2.3* | UMT 3.3* |

|---|---|---|---|---|

90% < 100 µm | 400 kg/h | 800 kg/h | 1400 kg/h | 2000 kg/h |

90% < 200 µm | 600 kg/h | 1200 kg/h | 2000 kg/h | 3000 kg/h |

Particle size | UMT 4.3* | UMT 5.3 | UMT 6.3 |

|---|---|---|---|

90% < 100 µm | 2800 kg/h | 4500 kg/h | 7500 kg/h |

90% < 200 µm | 4200 kg/h | 6500 kg/h | 12000 kg/h |

Roller Mills

Bauermeister Roller Mills are recommended for sugar grinding when a relatively coarse particle size (>0.2 mm) in addition to a low amount of fines is required. A popular example is sugar intended for instant drink production.

Sugar grinding capacities of different Roller Mill sizes

Particle size | 250.2 x 500 | VWR250.2 x 900 | 250.2 x 1300 |

|---|---|---|---|

5-10% < 100 µm and 95% < 1 mm | 1400 kg/h | 2500 kg/h | 3500 kg/h |

15-20% < 100 µm and 95% < 600 µm | 1000 kg/h | 1800 kg/h | 2600 kg/h |

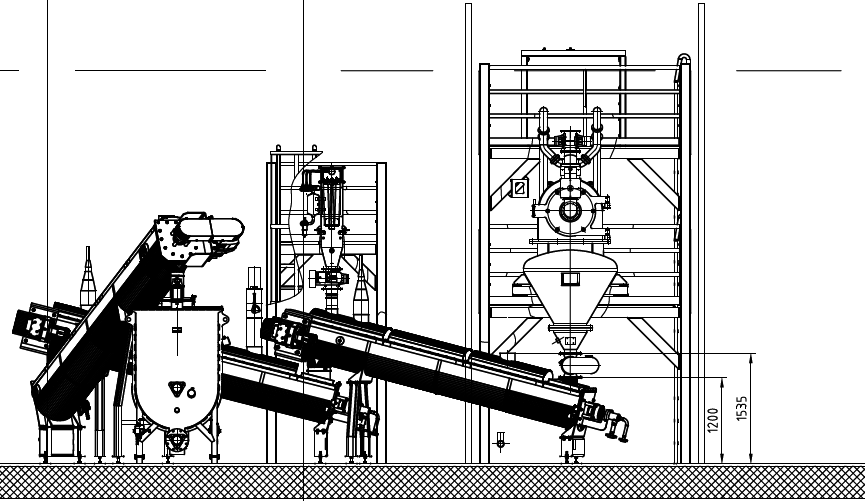

Sugar Conditioning

Freshly ground icing sugar tends to clump together. Anti-caking agents such as starch or calcium silicate are often added in small amounts to prevent this. If an additive free product is favored, conditioning is necessary to prevent clumping of the icing sugar. For this purpose, the icing sugar must be heated and moved. The excess moisture released during recrystallization must be removed. This is realized with two heating screw conveyors. The product is then cooled down again using a cooling screw conveyor.

After conditioning, the icing sugar is in a state of equilibrium with the environment and can be stored for a minimum of six months in conventional storage (max. 60 % RH) without clumping.

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.