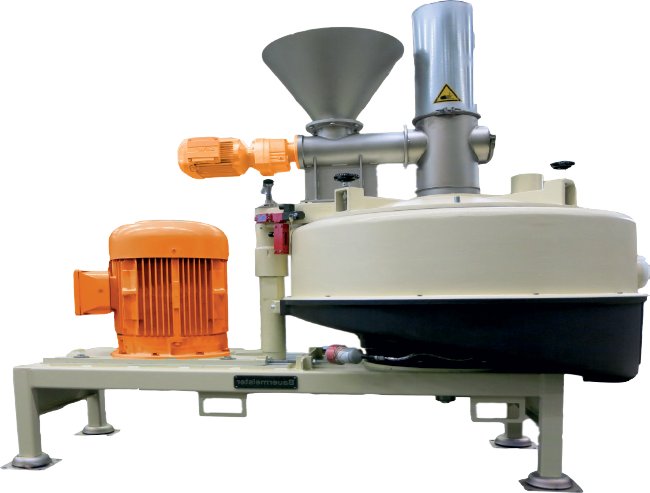

Beater Blade Mill SMM

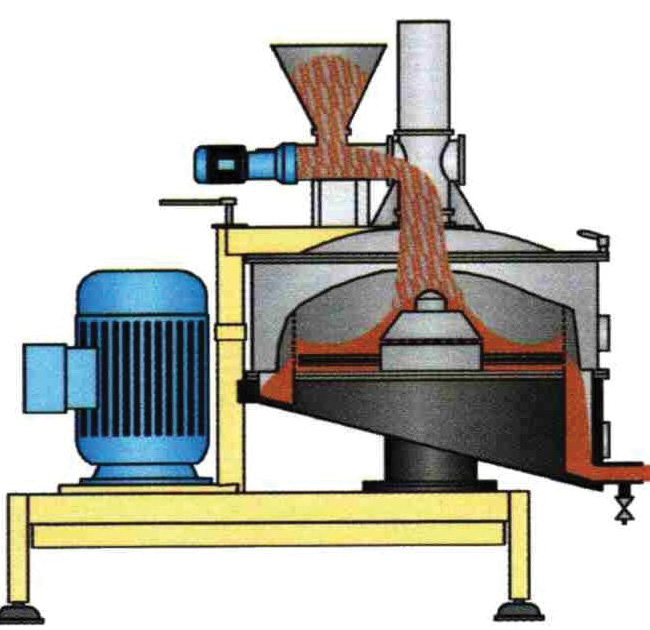

The product is fed into the grinding chamber at a controlled rate, by means of a dosing screw. High speed rotating blades break the product down to the required particle size and the high fat content ensures conversion into a pumpable mass with optimal flow properties. The fineness of the finished product is determined by the mesh size of an integral, annular sieve, through which the mass flows on its way to the exit of the mill.

The shell and base of the grinding chamber are of jacketed design, to facilitate the processing of product under controlled conditions of operation; hot or cold water is circulated, as appropriate, to maintain a constant temperature. The moisture content is also reduced during the grinding process.

- Continuous grinding. Non or un-sufficiently ground particles remain inside the grinding chamber. The subsequent plant components such as roll refiners will be wear protected.

- High capacity at a constant fineness.

- Determination of the requested fineness by choosing the mesh width of the sieves (0.15 – 0.5 mm).

- The achieved particle size spectrum favors the subsequent fine grinding by means of ball mills and roll refiners.

- Controlled product temperature.

- Fast exchange of blades and sieves due to swiveling cover.

- Short maintenance breaks, since the sense of rotation can be changed.

- The mill is equipped with automatically operated grease lubrication.

- Cleaning of the sieves can be done without its removal.

| MODEL | SMM 801 | SMM 801.1 | SMM 1101 | SMM 1101.1 |

| Diameter of Grinding Chamber | 802 | 802 | 1140 | 1140 |

| Height of Grinding Chamber | 333 | 333 | 460 | 460 |

| Connected Load | 45 | 55 | 90 | 110 |

| Number of Beater Blades | 8 | 8 | 8 | 8 |

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.