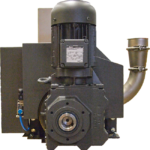

Roll Feeding Device WSV

Depending on the feed product properties and desired throughput Bauermeister Roller Mills can be equipped with different dosing systems. The Bauermeister Roll Feeding Devices WSV (One- or Two-Roller Feeder) were specially designed for all Bauermeister Roller Mills and enable a precise and continuous dosing along the total length of the main roll. It ensures an even load of the machine and individual-particle comminution even with feed products that are non-homogenous or contain large agglomerates.

This low maintenance feeder can minimize the roll wear of the machine’s main rolls and allows even dosing of non-homogeneous products or products with the tendency to agglomerate.

Product is dosed volumetrically with both versions of the WSV and deagglomerated simultaneously, either between two grooved rolls or between a grooved roll and a slanting plate. All product contact parts are made of stainless steel. The main components are two grooved rolls or one grooved role with a slanting plate and an upstream dosing valve. The roll speed as well as the gap between the rolls allows a continuous adjustment of the feed rate. A closed gap between the rolls or a closed dosing valve ensures a complete stop of product feed, allowing a secure stop of the roller mill. The gap is pre-adjusted mechanically, during operation it is opened and closed pneumatically with the start/stop of the machine to avoid product feed to the machine after stopping the main rolls.

- Product contact parts in stainless steel

- Available in various lengths corresponding to all Bauermeister Roller Mill sizes

- Dust-tight design

- Two connection points for additional aspiration

- Geared motor and chain drive

- Pneumatic as well as mechanical roll adjustment

- Length and throughput according to the size of the Bauermeister Roller Mill

- Roll speeds: 5 – 28 rpm

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.