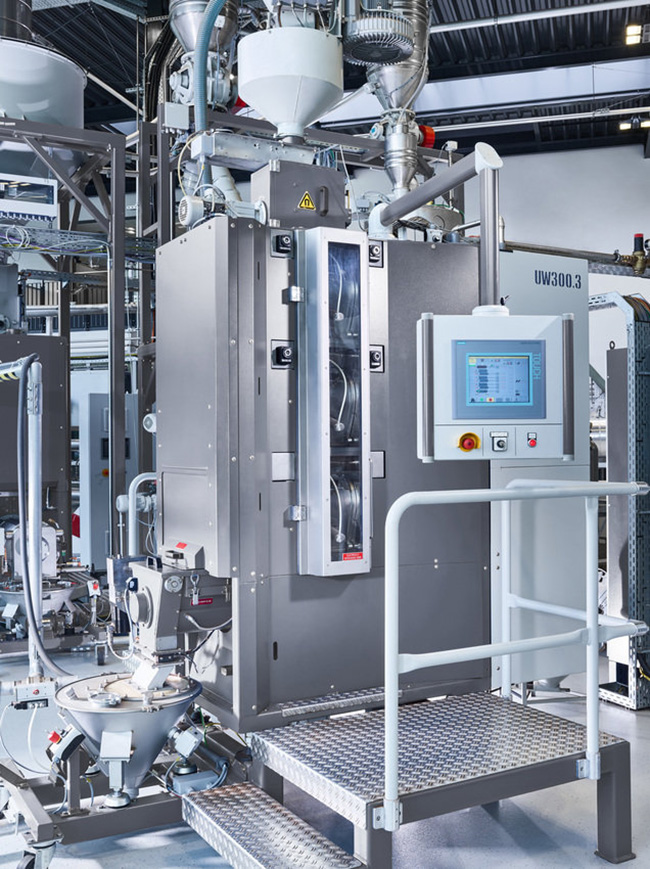

Roller Mill UW 300

Designed to grind brittle to hard products to a narrow particle size distribution with maximum optimization.

The UW 300 offers:

- Size reduction by shearing forces and pressure

- Narrow particle size distribution with minimal dust content

- Minimal mechanical impact and temperature increase of product

- Low specific energy consumption

- Customized roll material and surface

- Easy access for maintenance and cleaning

- High durability of rolls

- Modular machine setup with 1, 2 or 3 grinding stages

- Water cooled / heated rolls optional

- Precise manual gap adjustment system

- Stainless steel for all product contact parts

- Dust tight grinding chamber

- Double roll feeding device

- Magnetic separator

- Aspiration connection

- Roll diameter: 230 mm

- Roll length: 300, 600 & 900 mm

Model Range

UW 300.1 – one stage

UW 300.2 – two stage

UW 300.3 – three stage

- Patented automatic roll gap adjustment and gap monitoring system available

- Each roll is independently driven for optimal adjustment capability

- Bearing temperature and vibration sensors

- Active cleaning of grinding chamber

- Inerting of the grinding chamber is possible

- ATEX conformity

FOOD

- Coffee

- Grains

- Herbs/Spices

- Nuts

- Oil Seed

- Sugar

- Sugar Substitutes – Xylitol, Malititol, Sorbitol…

- Chemical

- Fertilizers

- Minerals

- Organic Fertilizer

- Super Absorbent Polymers

- Urea

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.