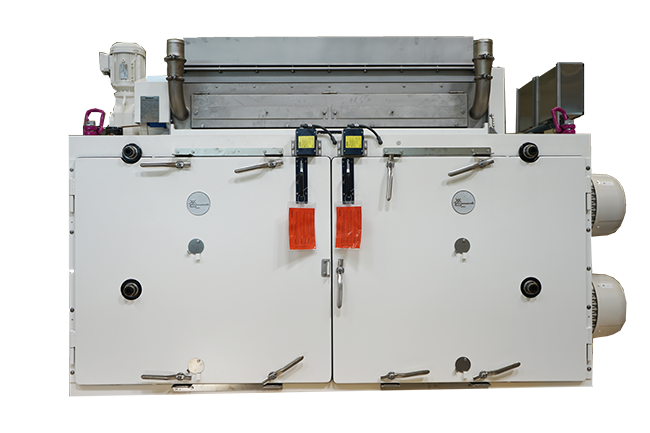

Roller Mill 400

Designed to grind brittle to hard products to a narrow particle size distribution with minimal dust content.

The 400 series of one- two- and three-stage roller mills offers:

- High throughput

- Narrow particle size distribution with minimal dust content

- Minimal mechanical impact and temperature increase of product

- Efficient energy initialization

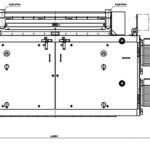

- Low space requirement

- High durability of rolls

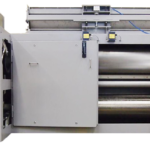

- Easy access to all machine components

- Efficient roll change and maintenance times

- Roll feeder

- Manual gap adjustment system

- Optimal roll protection against foreign particles includes in the feed-stock

- Dust-tight grinding chamber

- Sampling sockets in each passage

- Roll diameter: 400 mm

- Roll length: 2,100 mm

- Drive Power: 45 kW

Model Range

ZWR 400.1 – one stage

VWR 400.1 – two stage

SWR 400.1 – three stage

- Automatic roll gap adjustment and gap monitoring

- Stainless steel for product contact parts

- Aspiration connections

- Temperature monitored roll bearings

- Automatic roll bearing lubrication

- Vibration monitoring

- Potential compensation against static charges

- Product specific roll materials and corrugations

- Water cooled rolls

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.