Gap Mill GM-D

Bauermeister Gap Mills operate successfully in a wide range of applications for grinding soft to medium-hard materials such as sugar, starch, pectin, etc. up to a hardness of approx. 4-5 Mohs. Gap Mills are mainly used in the food, chemical and mineral industry for fine and ultra-fine grinding.

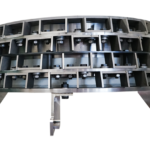

The material to be ground is fed at a controlled rate into the mill, where it is accelerated towards the outside perimeter on the cover plate of the rotor. The material being ground is pre-crushed at the upper edges of the fine-grinding elements and is then forced through the grinding gap between rotor and stator by air-suction. Grinding is continued by impact along the edges of the U-shaped grinding elements while passing through the grinding gap on the outside circumference of the mill. The product/air mixture is sucked through the tangential discharge pipe at the bottom.

- Easily adjustable grinding gap (1 to 5 mm)

- Variable rotor speed up to 123 m/s

- 3 sizes

- Highly reliable and sturdy mechanical design

- Maintenance-friendly, low non-productive times

- Welded structure

- Explosion pressure shock resistant up to an overpressure of 10 bar

- EU guideline 2014/34/EU – ATEX – compliant

- Designed to avoid product built-up inside and outside the mill

- Bearing temperatures constantly monitored

| Gap MIll Series GM | Capacity Factor | Air Volume (m³/min) | Motor Power (kW) |

| 40.1 | 1.0 | 30 | 30 |

| 80.1 | 1.8 | 60 | 75 |

| 120.1 | 2.8 | 100 | 160 |

- Carbon or Stainless steel design

- Wear resistant grinding tools

- Cryogenic grinding

- Automatic lubrication

- Vibration monitoring

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.