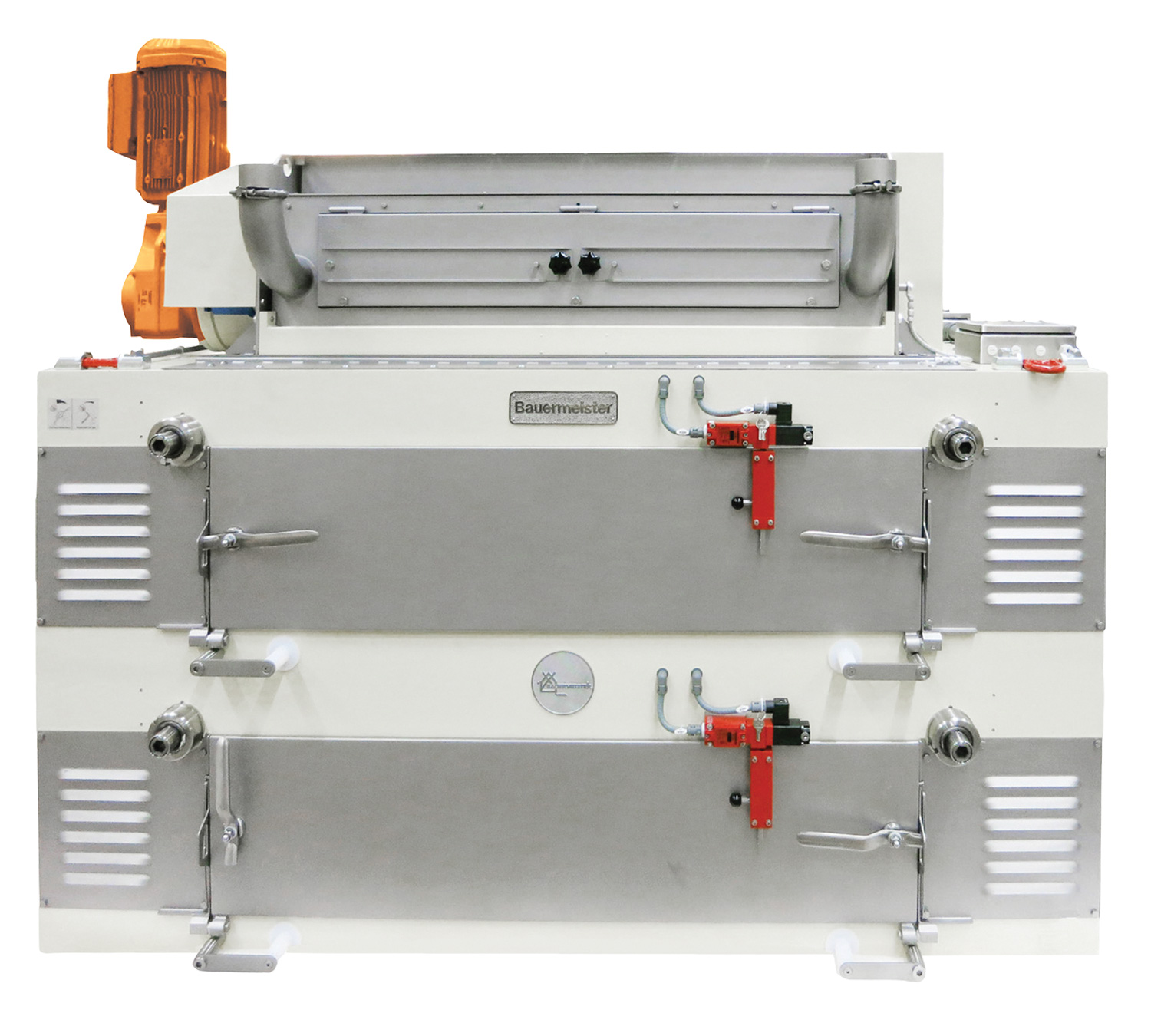

Roller Mill 250.2

The Bauermeister Roller Mill Series 250.2 are roller mills designed for effective grinding of brittle to hard products to a narrow particle size distribution with minimal dust content and a minimal product temperature rise. Their modular design facilitates flexible applications from one stage to three stage grinders.

For more advanced roller mills with even more features and options the Bauermeister 250.3 Series was developed. If larger throughputs are required Bauermeister has designed high performance Roller mills such as the 350 and 400 Series.

Bauermeister Roller Mills are reliable, sturdy machines with a long roll life and short maintenance times, designed for the grinding to a narrow particle size distribution with minimal dust content, minimal mechanical impact and temperature increase to the product. A dust-tight design, low space requirement and low noise emission are some of the reasons for the popularity of Bauermeister Roller Mills.

Bauermeister Roller Mills 250.2 Series can be equipped with one, two or three pairs of rollers making up the grinding passages in modular design. It is available in various sizes ranging from 500 to 1300 mm roller length, depending on the required throughput. Typical applications include the fertilizer, oilseed and the food industry.

As an optional feature a special ATEX conformed roller mill is available for products with a high risk of dust explosion.

- Individual drive of each roll

- Sturdy, single frame steel construction

- High durability of rolls

- Modular design: available as one-, two- and three-stage roller mill

- Enclosed drive section

- Compact design and low space requirement

- Product guides in the grinding chamber

- Stainless steel for all product contact parts (except rolls)

- Product specific feed unit (Vibration feeder / WSV)

- Manual roll gap adjustment via a dial scale

- Dust-tight grinding chamber

- Easy access to all machine components

- Efficient roll exchange and maintenance times

- Sampling sockets in each passage

- Roll retraction on contact with foreign body included in feed material

- Roll diameter: 250 mm

- Roll length: from 500 to 1300 mm

- Drive power: 15 to 22 kW per stage

Model Range

ZWR 250.2 – one stage

VWR 250.2 – two stage

SWR 250.2 – three stage

- Magnetic separator

- Aspiration possibility

- Water cooled rolls

- Different roll cleaning mechanisms available

- Inertization of grinding chamber (N2, CO2)

- All components are available in ATEX compliant execution

- Vibration monitoring

- Temperature monitored roll bearings

- Automatic roll bearing lubrication

- Contact-free compressed air sealing of the roll bearings

- Product specific roll materials and corrugations

- Potential compensation against static charge

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.