Limestone Grinding

The main application for limestone is as hydrated lime (calcium hydroxide) for mortar or plaster preparation. On a smaller scale, lime is additionally used as a fertilizer, for wastewater treatment or as an additive in the food industry (for example as a neutralizing agent or acidity regulator). Ground natural limestone is often used as a filler, a white pigment or as a reagent in flue-gas desulfurization.

Hydrated lime is produced from limestone in a two-step procedure. Limestone is burnt to calcium oxide (quicklime) and in a second step water is added to create hydrated lime. Bauermeister mills can be used for grinding natural limestone as well as burnt lime to the desired particle size. Hydrated lime reacts with carbon dioxide to create calcium carbonate. This reaction (desired for mortar) rules out grinding of hydrated lime on a mill as it would take place inside the mill and lead to clogging. Due to this a necessary grinding step needs to be situated before the hydration step of lime.

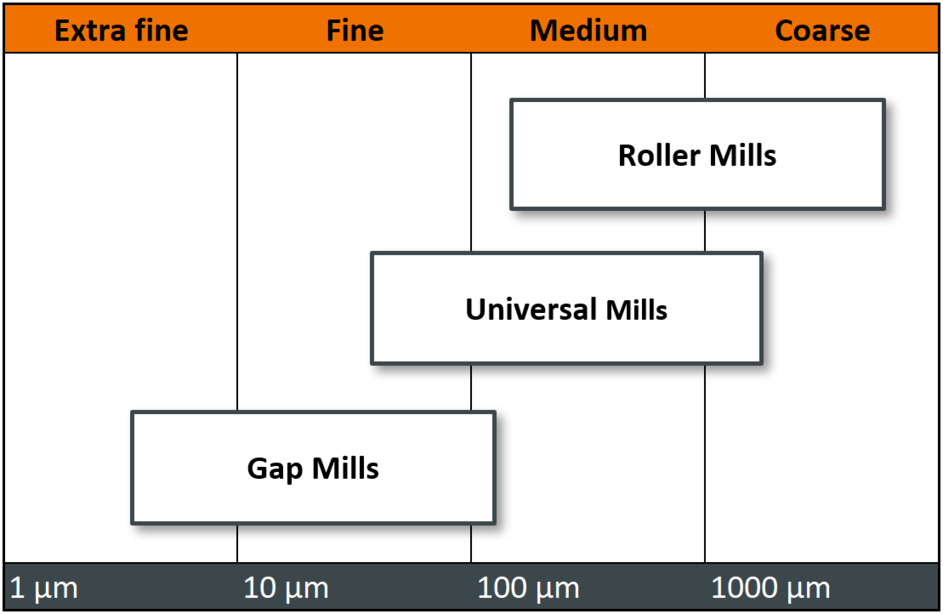

Roller Mills, Universal Mills and Gap Mills

A high number of Bauermeister mills are in operation for limestone and lime (calcium oxide) grinding all around the world. Depending on the required product fineness and output rate an optimal combination of milling parameters is available. These can be determined in trial grindings in our Technology Center. The decision for one of the many different grinding plant variations depends on the general conditions as well as the requirements of the customer. Bauermeister specialists will gladly assist you in the assessment of these characteristics and help chose the correct mill and plant type that matches your requirements.

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.