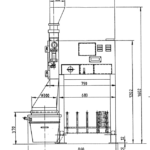

Laboratory Roller Mill LRC

Milling parameters such as the grinding gap between the rolls, roll speed as well as roll differential speed are easily and infinitely adjustable. An Easy-Lock roll clamping system allows a straightforward changing of a roll in less than a minute. A wide range of available roll profiles from smooth to different corrugations round up the LRC as the perfect machine for product development as well as process optimization. Trial grinding can be carried out with samples as small as 0.5 kg per run.

The grinding chamber and the product collecting bin are of stainless steel. The grinding process can be monitored and assessed through an acrylic glass cover plate. Each roll has a separate drive motor controlled by a frequency converter. Roll gap adjustment is carried out with a micrometer screw and can be adjusted infinitely between 0.1 and 15 mm. A simulation of multiple grinding steps with different rolls is possible.

- Dust-tight design, assembled ready for operation

- Vibration feeder or roller feeder and feed hopper in stainless steel

- Grinding chamber and ground product collection bin in stainless steel

- Transparent, acrylic glass cover plate for process observation

- Easy roll change by manually operated hydraulic Easy-Lock system

- Infinite gap adjustment by means of a precision spindle

- Roll speed individually and infinitely adjustable between 0 and 12 m/s

- Roll retraction safety system to prevent roll damage in case of impurities contained in the feed material

- Roll diameter: 250 mm

- Roll length: 80 mm

- Drive: 2 x 1.5 kW

- Roll circumferential speed: 0 – 12 m/s

- Rolls: smooth or various corrugations

- Product feed: vibration or screw feeder or roll feeding device (laboratory size WSV)

- Special design with product collecting bin for continuous operation available

- Aspiration for dedusting of the grinding chamber possible

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.