Gypsum Grinding

Gypsum was already used by the Greeks and Romans as building material for plastering walls and producing artful ornaments.

Today gypsum is offered in many variations, for instance chemical additives can extend the solidifying time or increase the fire resistance of gypsum. The addition of fibers into the gypsum allows the production of fibre walls, covering gypsum with paper produces the widely spread plasterboards used to build drywalls and divide rooms inside houses.

The raw gypsum is usually won in quarries or in mines. After several size reduction steps it is heated in rotary kilns and subsequently ground in a mill to its desired final particle size distribution.

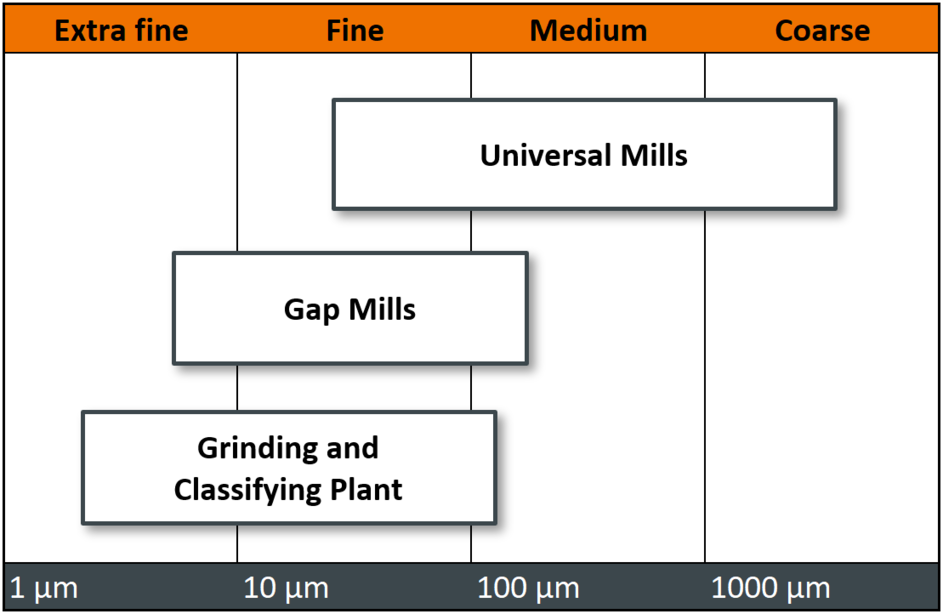

Universal Mills, Gap Mills and Air Classifiers

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.