Aluminum Oxide Grinding

Universal Mills, Gap Mills and Classifiers

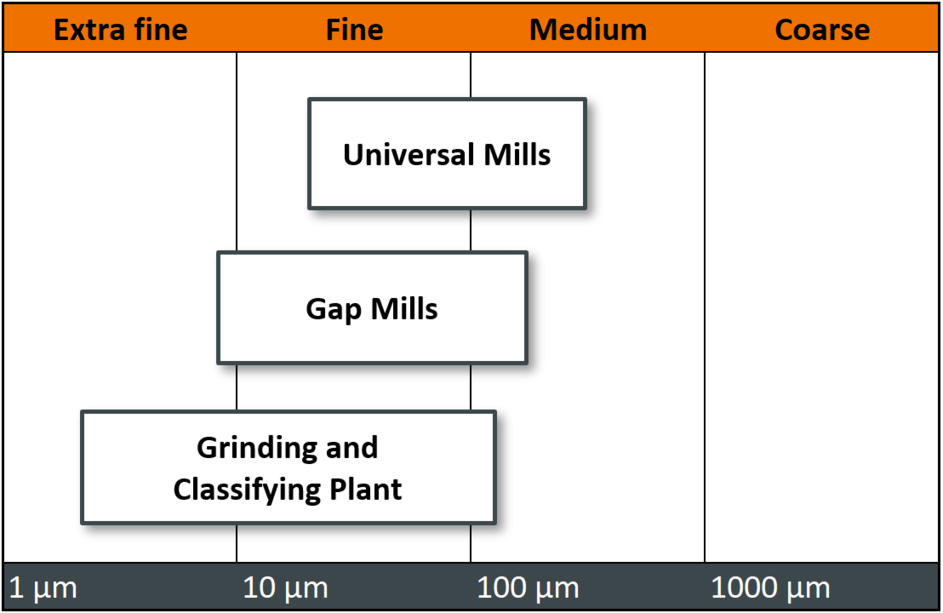

A high number of Bauermeister mills are in operation for the grinding of alumina all around the world. Depending on the required product fineness and output rate an optimal combination of milling parameters is available. These can be determined in trial grindings in our Technology Center. The decision for one of the many different grinding plant variations depends on the general conditions as well as the requirements of the customer. Bauermeister specialists will gladly assist you in the assessment of these characteristics and help choose the correct mill and plant type that matches your requirements

Have Questions Or Interested In Our Products?

Please let us know. Our service and support team is always available for you and your questions.

Don’t hesitate to contact us.