Gelling Agent Grinding

Gelling or thickening agents are added to different food or non-food liquids to increase its viscosity without influencing taste or other non-textural properties. Edible thickeners in the food industry used for thickening sauces, soups or puddings include modified starches, gelatine and pectin.

Many Bauermeister mills are established all around the world for the grinding of gelling agents. For every application there is an optimal combination of mill parameters depending on the desired fineness. The right mill setup and integration of the mill into a production plant depend on the general conditions as well as on the individual requirements of every plant operator. For the evaluation of the criteria, Bauermeister specialists are available for a competent consultation.

Pectin Grinding on Bauermeister Mills

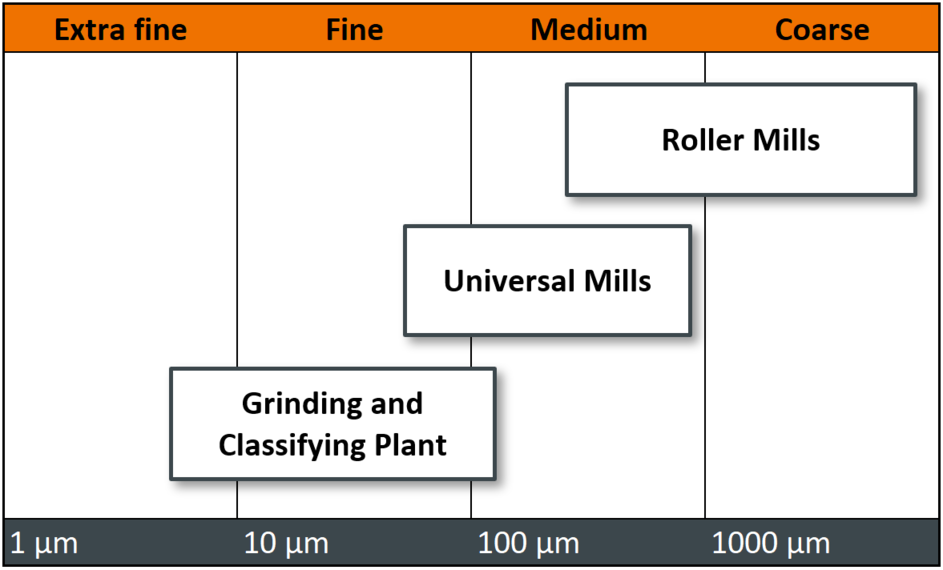

Most vegetables and fruits contain a certain amount of pectin, industrially pectin is mainly won from apple and citrus peel or press residue from juice production. Pure pectin won from fruit peels leaves the production process as a wool like material and needs to be ground to a fine powder to guarantee a steady product quality. Depending on the required particle size, different Bauermeister mills produce optimal results. Coarse products can be ground on a Bauermeister Universal Mill UM, for products finer than 99 % < 200 µm a Bauermeister Gap Mill GM is the mill of choice. If a pectin powder of 99 % < 100 µm or finer is required, a Bauermeister Air Classifier CL can be added to the GM.

Gelatin Grinding on Bauermeister Mills

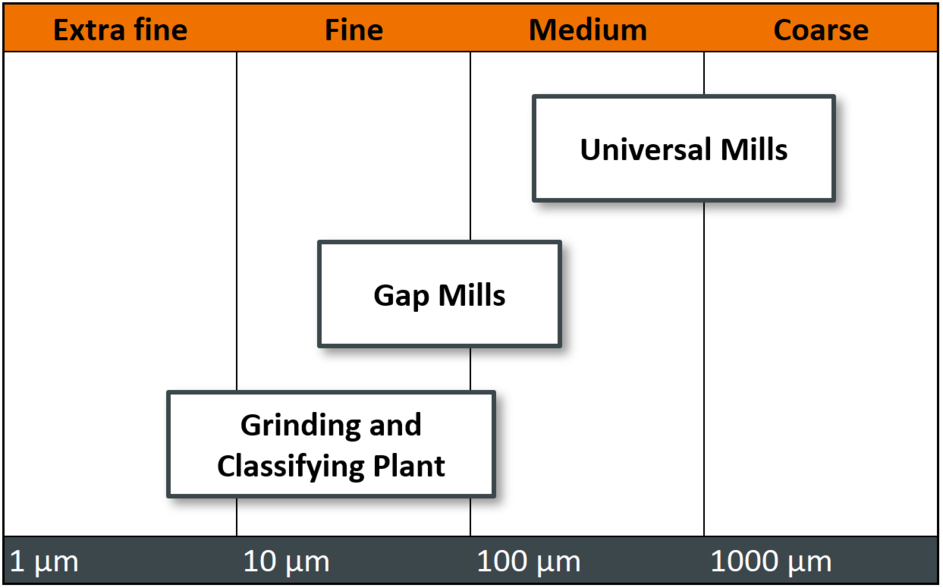

Gelatin is the first documented gelling agent with the first industrial production starting as early as the 18th century. It can be extracted from the skin and bones of cows or pigs. Depending on the intended use different particle size distributions of gelatin are required, ranging from > 1 mm to finer products under 300 µm. This wide range of sizes demands a great flexibility of the used mill. Bauermeister mills are found in many production sites for gelatin powder ranging from Universal Mill UM for fine products to Roller Mills for dust free coarser gelatin powder. As gelatin is a temperature sensitive product cooling the grinding process is often necessary and can be realized by cooling of the process air in an UM or cooling of the rollers in a Roller Mill.